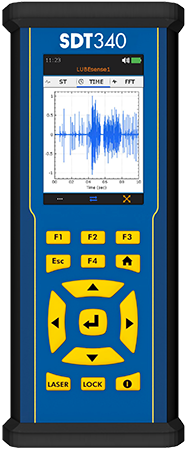

SDT 340

CLOUD CONNECTED CONDITION MONITORING

Detect, measure and analyze ultrasound and vibration

Brochure

USE THE SDT270 ULTRASOUND SOLUTION FOR A NUMBER OF APPLICATIONS IN YOUR PRODUCTION:

- Condition monitoring of mechanical parts

- Monitoring of bearing lubrication

- Detection of compressed air & gas leaks

- Detection of defects in electrical equipment

- Test and maintenance of steam traps

- Monitoring of hydraulic systems

- Condition monitoring of valves

- Tightness testing

DOWNTIME IS A CONSTANT THREAT TO YOUR EQUIPMENT.

It is a fact: all machines can break down. You need a solution that can predict these defects at an early stage. Plan your maintenance work on your terms. Let SDT help you get your equipment back under control.

Against equipment failures, unplanned downtime in your production or expensive last-minute repairs, you need a measurement device that helps you optimise your effective operating time, reduce energy and maintenance costs and keep your equipment under control.

In detail

- Display the time signal, the spectrum or the history of measurements on the SDT340 screen.

- The FocUS mode identifies the impact phenomena in a signal and thus incipient defects on bearings and gears.

- Recording time for long-time signals. Up to 32,000 samples per second for 10 minutes.

- Navigate between time and frequency signals with scroll and zoom. Display of the 10 highest values.

- View previous measurements to immediately evaluate the evolution of the problem.

- Bluetooth headset for safe and intensive use in noisy industrial environments.

- 3 methods of measurement collection with intuitive navigation within a tree structure. The recording of measurements is adapted to each situation.

- The 3.5 inch colour screen is perfectly legible in dark places.

Specifications

| Geschikt voor | gas, lucht, vacuum of stoomlekken, lagerdefecten en storingen in elektriciteitskasten |

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience

Tailor-made technical advice

Tailor-made technical advice