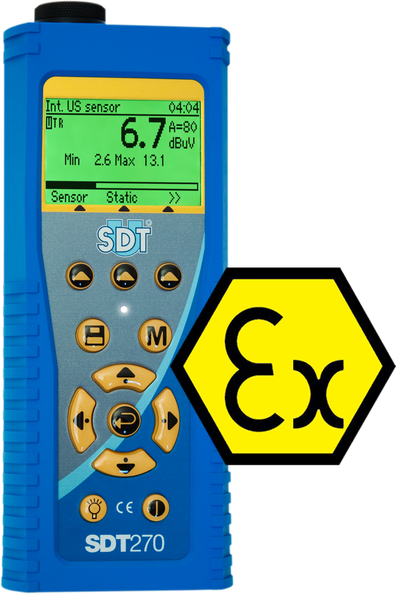

SDT 270, ATEX-Edition

The SDT270 ultrasound detector gives you greater insight into the health of your equipment.

It helps you control energy costs, predict failures, improve product quality and increase overall trouble-free production time.

Brochure

Use the SDT270 ultrasound solution for a number of applications in your production:

- Condition monitoring of mechanical parts

- Monitoring of bearing lubrication

- Detection of compressed air & gas leaks

- Detection of defects in electrical equipment

- Test and maintenance of steam traps

- Monitoring of hydraulic systems

- Condition monitoring of valves

- Tightness testing

Downtime is a constant threat to your equipment.

It is a fact: all machines can break down. You need a solution that can predict these failures at an early stage. Plan your maintenance work on your terms. Let SDT help you get your equipment back under control.

Against equipment failures, unplanned downtime in your production or expensive last-minute repairs, you need a measurement device that helps you optimise your effective operating time, reduce energy and maintenance costs and keep your equipment under control.

Your SDT ultrasound solution allows you to predict and prevent failures before they happen. Stop relying on the reactive, punitive measures of the past and take a proactive approach.

Specifications

| Geschikt voor | gas, lucht, vacuum of stoomlekken, lagerdefecten en storingen in elektriciteitskasten |

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience

Tailor-made technical advice

Tailor-made technical advice