R501

Le contrôleur de température à fibre optique le plus polyvalent, multicanal et robuste.

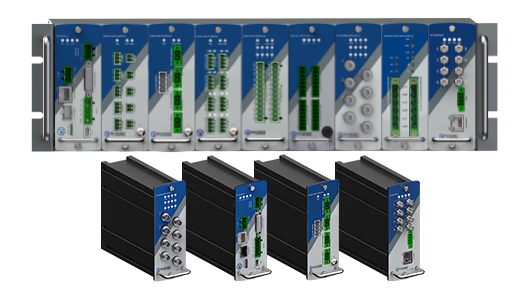

Rugged Monitoring R501

Increasing automation and centralisation across industries has created a need for a flexible and expandable monitoring system that can collect data from a wide variety of sensors and provide a single visualisation and control platform.

The Rugged Monitoring R501 is designed with built-in flexibility and expandability to meet the changing needs of customers. The R501 solution provides real-time monitoring of fiber optic temperature and many other parameters such as pressure, AC current, AC voltage, DC current, binary inputs, etc. Different kinds of input/output (IO) modules (analogue input, digital input, analogue output, digital output) are available to fit into the chassis. It supports both rack mounting and decentralised installation. The R501 chassis can be installed in a customer control panel and provides flexibility for testing/monitoring up to 256 sensors. The FO modules and other IO modules can also be installed independently (Din rail mounting) and connected in series to the central CPU module communicating via CANBUS/MODBUS. Distributed modules can also be directly connected to a customer data logger for high resolution data logging, e.g. CAN-Logger. Together with the R501, advanced 'Rugged Connect' software is available for data visualisation, configuration and reporting.

The R501 can be used in a wide range of applications, including aerospace, automotive, cryogenic, battery banks/racks, medical, semiconductor, utility and R&D. Its wide measurement range (-271 °C to +300 °C), high accuracy and full immunity to RFI, EMI, microwave radiation and high voltages make it an obvious choice for temperature measurement in extreme conditions.

APPLICATIONS

- Testing of electric vehicles and batteries

- Testing of medical equipment (MRI, PETSCAN, NMR)

- Battery rack monitoring, Fire Code Compliance

- Testing of aircraft and fuel tanks

- Commercial Microwave Radiation

- Industrial process control and monitoring applications

- Chemical and process industries

- Food and beverage processes

- Transformer Monitoring with Winding Hotspot Temperature

- Electric Motors and Generator Testing

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience

Tailor-made technical advice

Tailor-made technical advice